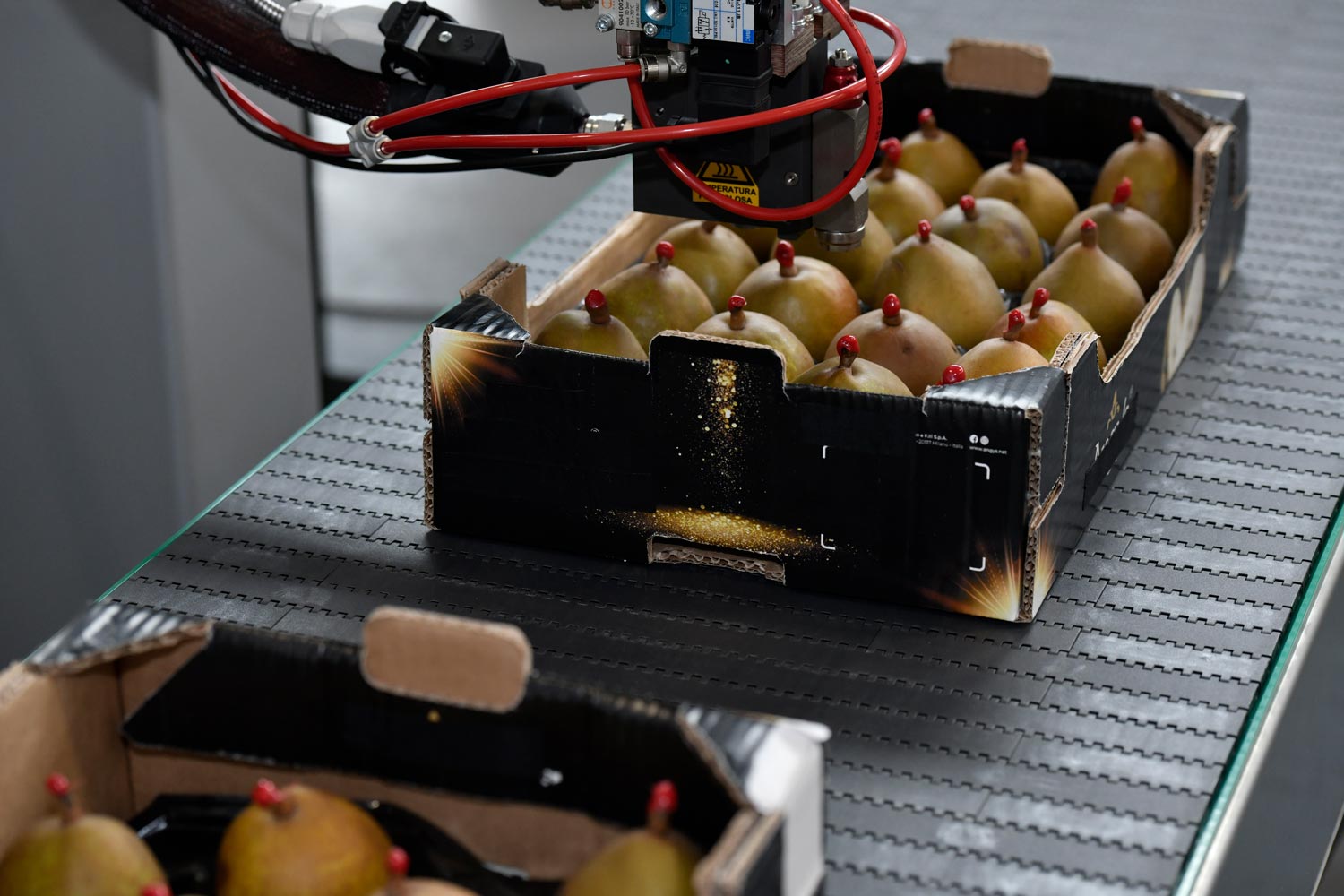

Automated wax sealing is the core service offered by Conkreta Robotics, designed to revolutionize the way fruit is handled and presented. Our advanced system guarantees a series of advantages that significantly improve the quality of the final product.

Watch the video and discover our automated sealing wax technology in action.

Thanks to our automated systems, each fruit receives an exact amount of wax, ensuring uniform and homogeneous coverage. This level of accuracy is not achievable with manual methods, which can vary greatly from one operator to another.

Our system guarantees precise dosage of the wax, eliminating waste and ensuring that each fruit has the right amount of coating. This optimal control helps keep costs under control and reduce environmental impact.

Conkreta Robotics’ advanced technology ensures that the wax is dispensed cleanly, without smears or residues. This results in a final product that appears elegant and refined, much more presentable than traditional methods.

Fruit sealed with wax using the Conkreta Robotics method is visibly more elegant and refined. Unlike manual methods, which often leave smudges and irregularities, our automated system guarantees an impeccable appearance, enhancing the presentation of the products.

Conkreta Robotics offers two innovative solutions for fruit wax sealing: a “Static” option for precise application in controlled environments and a “Dynamic” solution for continuous and efficient processing in the production line.